Optimization of a plate subjected to buckling loads#

The code snipets are supposed to present the major functionalities of composipy.

Plate buckling analysis#

The buckling_analysis() core method solves a eigenvalue problem like

where \([K]\) is the stiffeness matrix of the panel, \([K_G]\) is the geometrical stiffness matrix that depends on internal loads, \({c}\) is the vector of Ritz constants that determines the buckled shape and \(λ\) is the eigenvalue, that determines the critical buckling load. More details about this formulation are found at [1].

[1]:

from composipy import OrthotropicMaterial, LaminateProperty, PlateStructure

#Ply Material Properties

E1 = 60800 #MPa

E2 = 58250 #MPa

v12 = 0.07

G12 = 4550 #MPa

t = 0.21 #mm

# Plate geometry

a = 360. #mm

b = 360. #mm

m = 7 # discretization in x direction

n = 7 # discretization in y direction

# Stacking sequence

stacking = [45,-45,0,90,45,-45,0,90,45,-45] #angles in degrees

stacking += stacking[::-1] # symmetry

material = OrthotropicMaterial(E1, E2, v12, G12, t)

laminate = LaminateProperty(stacking, material)

# Plate boundary conditions

constraints={

'x0': ['TX', 'TY', 'TZ'],

'xa': ['TX', 'TY', 'TZ'],

'y0': [],

'yb': ['TX', 'TY', 'TZ'],

}

#Plate loads

Nxx = -1

Nyy = -0.5

Nxy = 0.5

panel = PlateStructure(dproperty=laminate, a=a, b=b, m=m, n=n, Nxx=Nxx,

Nyy=Nyy, Nxy=Nxy, constraints=constraints)

eigenvalue, eigenvector = panel.buckling_analysis()

print(f'Critical eigenvalue is {eigenvalue[0]: .1f} N/mm')

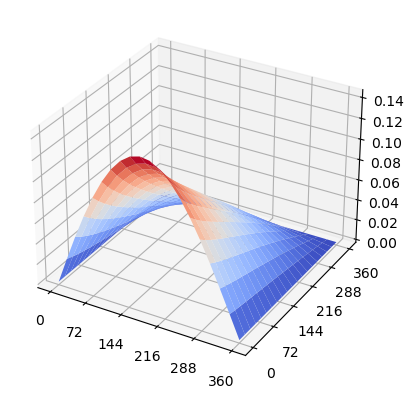

panel.plot_eigenvalue()

Critical eigenvalue is 26.6 N/mm

Maximize Critical Buckling Load#

The maximize_buckling_load() function solves a optimization problem like

that finds the pair of lamination parameters \(( W_1, W_3 )\) that maximizes buckling load, given the constraints \(g_1\) and \(g_2\). The flexural Lamination Parameters, established by [14], are

where \(θ_l\) is the angle of the laminate in continuous dominium and \(h\) is the laminate thickness. For practical reasons, only Lamination Parameters \(W_1\) and \(W_3\) are used as project variables, while \(W_2\) and \(W_4\) are considered equal zero, therefore a symmetric and balanced laminated is considered. For more details on how to interpret them and convert them into a feasible stacking sequence, check the references [1], [2] and [3].

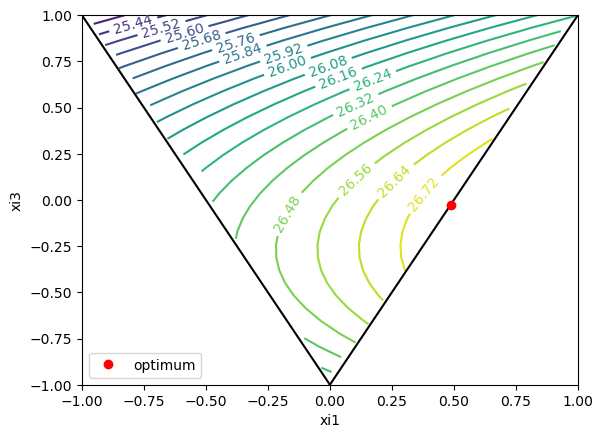

Objective function with boundary g1 and g2#

[4]:

from composipy.optimize import maximize_buckling_load

total_thickness = 20*0.21 #4.2 mm

res = maximize_buckling_load(a=a, b=b, T=total_thickness, E1=E1, E2=E2,

v12=v12, G12=G12, Nxx=Nxx, Nyy=Nyy,

Nxy=Nxy, m=m, n=n, panel_constraint=constraints,

plot=True, penalty=True) #remove plot=True to gain performance

print(f'W1={res.x[0]: .3f} and W3={res.x[1]: .3f}')

generating plot...

W1= 0.487 and W3=-0.026

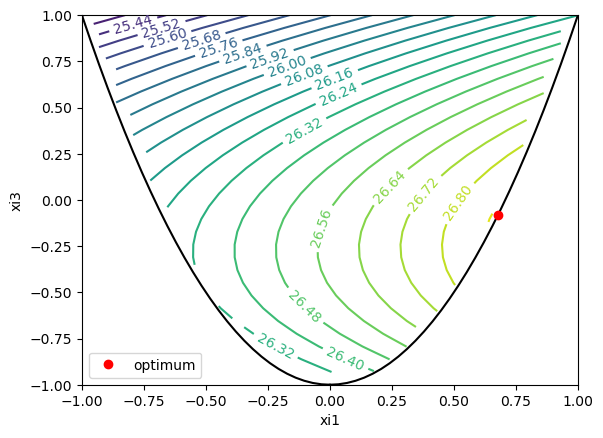

Objective function without boundary g1 and g2#

[3]:

total_thickness = 20*0.21 #4.2 mm

res = maximize_buckling_load(a=a, b=b, T=total_thickness, E1=E1, E2=E2,

v12=v12, G12=G12, Nxx=Nxx, Nyy=Nyy,

Nxy=Nxy, m=m, n=n, panel_constraint=constraints,

plot=True, penalty=False) #remove plot=True to gain performance

print(f'W1={res.x[0]: .3f} and W3={res.x[1]: .3f}')

generating plot...

penalty False

W1= 0.677 and W3=-0.083

Minimize Panel Weight#

The minimize_panel_weight() function solves a optimization problem like

that minimizes the volume of the plate submitted to the constraints \(g_1\), \(g_2\) and \(g_3\). Where \(T\), the total thickness of the plate, is used as design variable.

[3]:

from composipy.optimize import minimize_panel_weight

res = minimize_panel_weight(a=a, b=b, E1=E1, E2=E2,

v12=v12, G12=G12, Nxx=26.6*Nxx, Nyy=26.6*Nyy,

Nxy=26.6*Nxy, m=m, n=n, panel_constraint=constraints)

print(f'T={res.x[0]: .3f} W1={res.x[1]: .3f} and W3={res.x[2]: .3f}')

T= 4.190 W1= 0.487 and W3=-0.026

References#

[1] SILVA, Rafael Pereira da. Composite Plate optimization combining semi-analytical model, Lamination Parameters and a Gradient-Based Optimizer. 2023. 82f. Dissertation of Master of Science – Instituto Tecnológico de Aeronáutica, São José dos Campos.

[2] Miki, M. Sugiyama, Y. (1993). Optimum Design of Laminated Composite Plates Using Lamination Parameters. Aiaa Journal - AIAA J. 31. 921-922. 10.2514/3.49033.

[3] Gurdal, Z.; Haftka, R. T. Elements of Structural Optimization. Third revised and expanded edition. Springer-Science Business Media, B. V. 1991.