Critical Buckling Verification Study#

Presented within Rafael’s master dissertation “COMPOSITE PLATE OPTIMIZATION COMBINING SEMIANALYTICAL MODEL, LAMINATION PARAMETERS AND A GRADIENT-BASED OPTIMIZER”.

Access the full repository with complete study and NASTRAN FEM model at: rafaelpsilva07/rafaelmscdissertation

The following examples are part of the Ritz verification against FEM model.

Simply Supported study case (SSSS)#

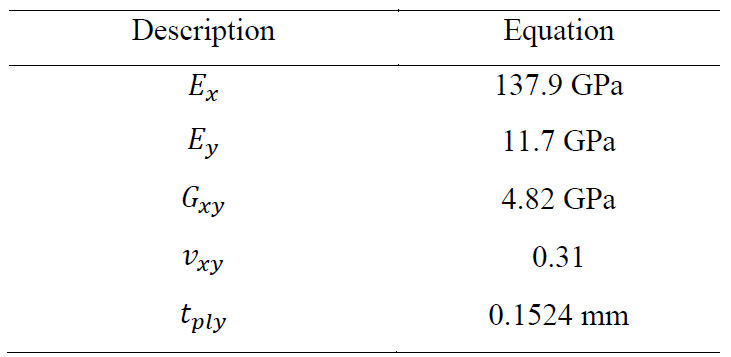

This study case aims to verify the Rayleigh-Ritz implementation made with Composipy (Silva, R.P. 2023). Mathematical verification of the Rayleigh-Ritz implementation is made against analytical buckling equation and FEM model. The benchmarking example is a simply supported plate with biaxial load, which considers a quasi-isotropic layup [(45/-45)2/02/902]s and properties according Table below. This example came from Kassapoglou (2010).

Dimension of the square plate is 100 mm and the load ratio (𝑁𝑦/𝑁𝑥) is 0.5. Analytical solution for this problem using Equation below is 234.7 N/mm.

This problem using composipy results in 225.9 N/mm. See code below.

[1]:

from composipy import OrthotropicMaterial, LaminateProperty, PlateStructure

[5]:

E1 = 137.9e3

E2 = 11.7e3

v12 = 0.31

G12 = 4.82e3

t = 0.1524

a = 100

b = 100

Nxx = -1

Nyy = -0.5

m = 7

n = 7

mat = OrthotropicMaterial(E1, E2, v12, G12, t)

stack = [45, -45]*2 + [0]*2 + [90]*2

stack += stack[::-1]

lam = LaminateProperty(stack, mat)

plate = PlateStructure(lam, a, b, "PINNED", Nxx=Nxx, Nyy=Nyy, m=m, n=n)

eigenvalue, eigenvector = plate.buckling_analysis()

print(f'min eigenvalue is {eigenvalue[0]: .1f} N/mm')

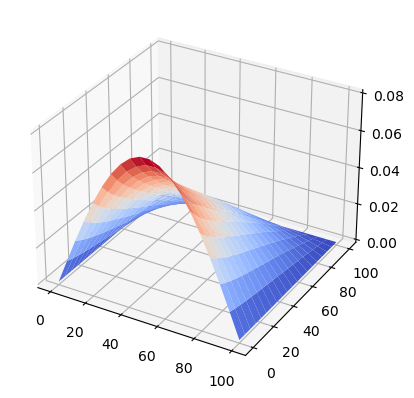

plate.plot_eigenvalue()

min eigenvalue is 225.9 N/mm

Different boundary conditions#

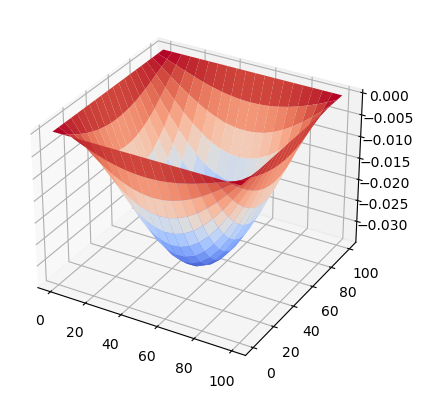

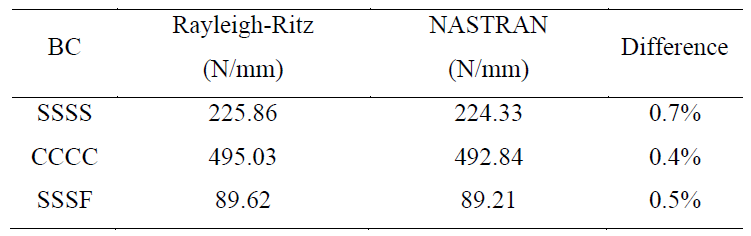

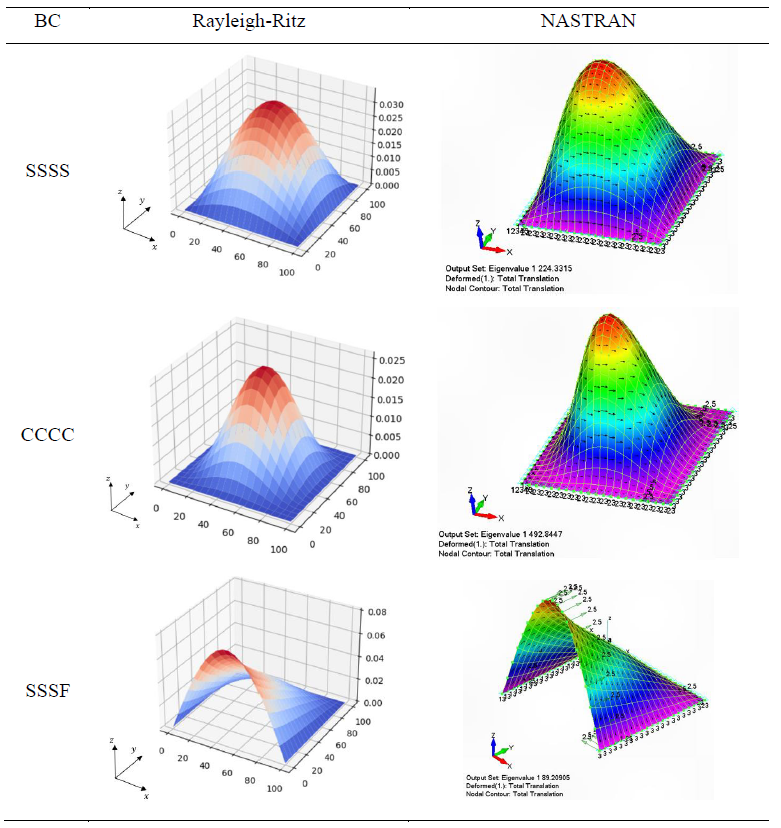

Table below extends the study for different boundary conditions in order to verify polynomial functions presented in section 2.1.3. The results are verified against a NASTRAN FEM model and the maximum difference is 0.7%. Table 6 presents the first buckling mode deformation shape.

Clamped study case (CCCC)#

[7]:

lam = LaminateProperty(stack, mat)

plate = PlateStructure(lam, a, b, "CLAMPED", Nxx=Nxx, Nyy=Nyy, m=m, n=n)

eigenvalue, eigenvector = plate.buckling_analysis()

print(f'min eigenvalue is {eigenvalue[0]: .1f} N/mm')

plate.plot_eigenvalue()

min eigenvalue is 495.0 N/mm

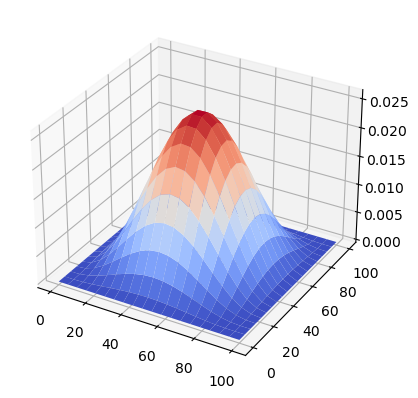

Simply supported with one free edge study case (SSSC)#

[9]:

constraints = {

'x0' : ['TX', 'TY', 'TZ'],

'xa' : ['TX', 'TY', 'TZ'],

'y0' : [],

'yb' : ['TX', 'TY', 'TZ']

}

plate = PlateStructure(lam, a, b, constraints, Nxx=Nxx, Nyy=Nyy)

eigenvalue, eigenvector = plate.buckling_analysis()

print(f'min eigenvalue is {eigenvalue[0]: .1f} N/mm')

plate.plot_eigenvalue()

min eigenvalue is 89.6 N/mm

Comparison with NASTRAN deformed shape#

References#

Kassapoglou, Christos. Design and Analysis of Composite Structures: With Applications to Aerospace Structures. John Wiley & Sons, 2010.